Fanless vs Fan-Cooled Mini PCs: Which is Better for Industrial Environments

Industrial Mini PC Showdown Fanless vs Fan-Cooled for Hystou Systems

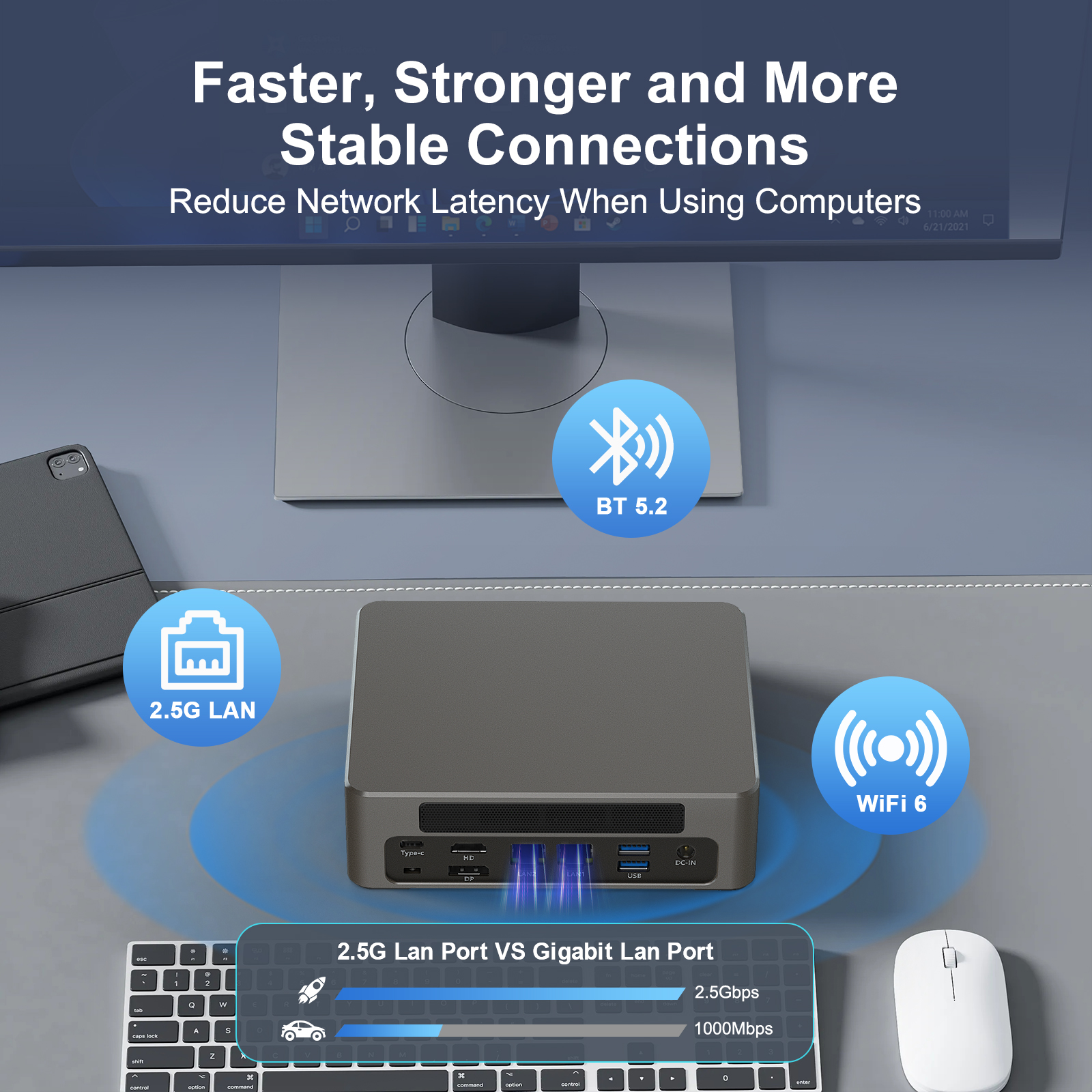

In the fast-paced world of industrial computing, the choice between fanless and fan-cooled mini PCs can have a huge impact on your operations. On one side, there’s the Hystou K4 with its appearance design, standing strong against dust. On the other hand, the H6 Fan-Cooled model boasts powerful Intel Core i7 processors. But which one truly fits your industrial needs? Let’s take a closer look at this critical decision.

The Industrial Challenge: Dust, Vibration and Extreme Temperatures

Industrial environments are tough on equipment. Factories are filled with dust, warehouses have extreme temperature swings, and production lines never seem to stop. Traditional computers often fail in these conditions, but Hystou’s industrial mini PCs are built to handle the heat, quite literally.

The K4 and H3 – N100 fanless models can operate in temperatures ranging from -20°C to 60°C. This is a game – changer for industries like food processing, where freezers and ovens create extreme temperature differences. In contrast, the H6 Fan – Cooled model, with its active cooling system, is better suited for controlled environments that need high – performance computing.

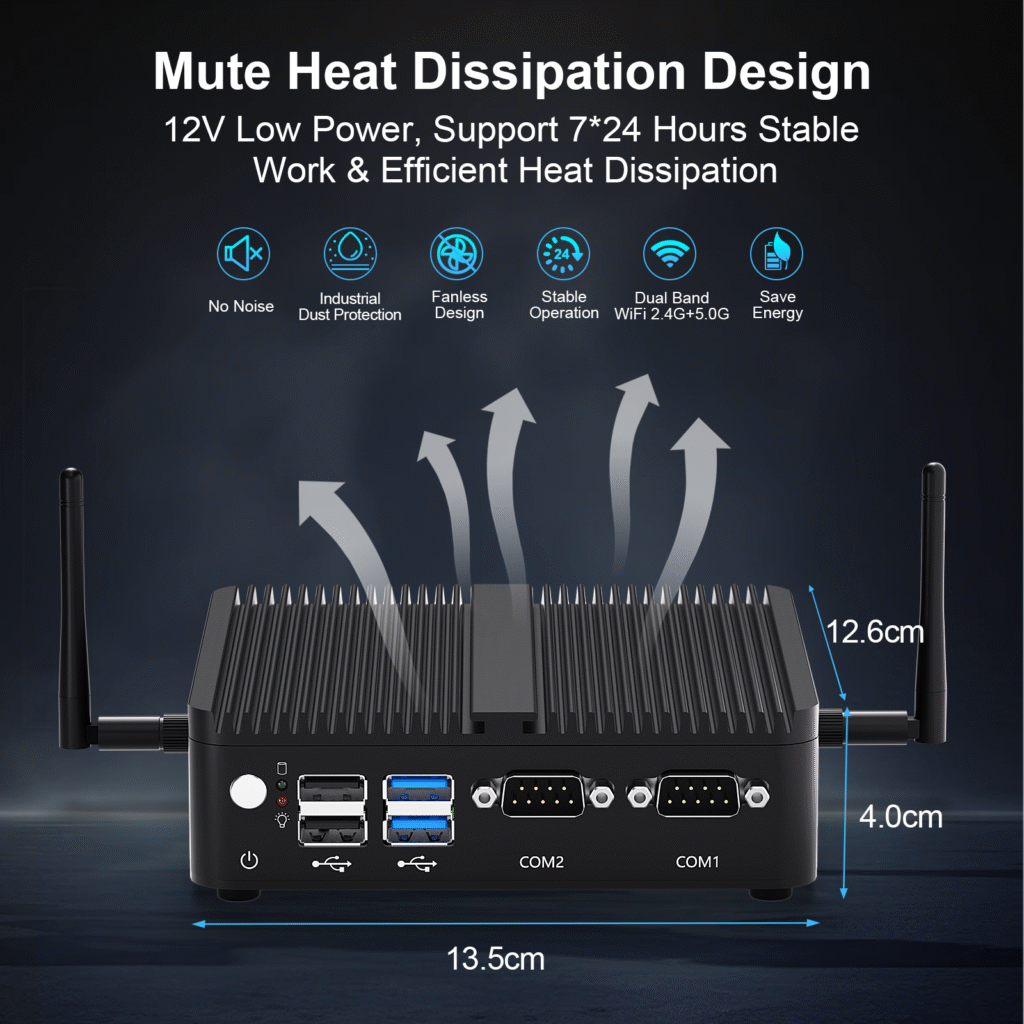

Fanless Design: The Silent Workhorse

The beauty of fanless design lies in its simplicity and reliability. Without fans, there are no parts that can wear out or get clogged with dust. This significantly reduces maintenance needs and downtime. In textile mills where lint fills the air or in mining operations with constant dust, the K4’s sealed design becomes a lifesaver.

The passive cooling system, combined with the aluminum chassis, does more than just dissipate heat. It also provides excellent electromagnetic interference (EMI) protection. This is crucial in environments with heavy machinery, where electrical noise can disrupt sensitive data acquisition.

One often overlooked advantage is silent operation. In noise – sensitive environments like laboratories or recording studios that still need industrial – grade computing, fanless systems are the only way to go.

Fan - Cooled Power: When Performance Matters Most

The H6 Fan – Cooled model is a powerhouse compared to its fanless siblings. The Intel Core i7 processor delivers significantly more computing power, making it suitable for tasks like real – time video analytics in smart factories or complex simulations in research facilities.

The multi – display capability is a standout feature. In control rooms where operators need to monitor multiple processes simultaneously, the ability to drive three independent displays from a single compact unit saves valuable space and reduces cable clutter.

However, this performance comes with trade – offs. The active cooling system requires regular maintenance to ensure the fan doesn’t get clogged with dust. In environments with heavy particulate matter, you might find yourself cleaning the fan filter monthly instead of the yearly maintenance required for fanless models.

Making the Decision: Key Factors to Consider

When choosing between fanless and fan – cooled industrial mini PCs, consider these critical factors:

Environment Conditions:

If your facility has extreme temperatures (-20°C to 60°C), high dust levels, or high humidity, fanless models like the K4 or H3 – N100 are the way to go.

For controlled environments where performance is paramount, the H6 Fan – Cooled model offers superior computing power.

Maintenance Requirements:

Fanless systems require minimal maintenance, making them ideal for remote locations or hard – to – reach installations.

Fan – cooled systems need regular fan and filter maintenance but provide better performance for intensive tasks.

Performance Needs:

Light to moderate tasks like basic automation, data logging, or simple HMI applications are perfect for fanless models.

Heavy computational tasks such as machine vision, complex simulations, or multi – display control systems benefit from the H6’s processing power.

Longevity and Reliability:

Fanless systems generally have a longer lifespan in harsh environments due to fewer moving parts.

Fan – cooled systems can provide more processing power but may require more frequent component upgrades to keep up with evolving performance needs.

Real - World Applications: Which Model Fits Your Industry

Let’s look at how different industries might benefit from each model:

Manufacturing: The K4’s 6 COM ports make it ideal for connecting to legacy PLCs and sensors on the factory floor. Its dust resistance ensures reliable operation even in machining environments.

Oil and Gas: The H3 – N100’s wide temperature range and rugged design make it suitable for both offshore platforms and onshore drilling operations.

Smart Cities: The H6 Fan – Cooled model’s processing power and multi – display capability are perfect for traffic management systems, where real – time video analytics and multiple camera feeds need to be processed simultaneously.

Food and Beverage: The IP65 rating of the K4 allows for washdown procedures in food processing facilities, ensuring compliance with hygiene standards.

Transportation: The H3 – N100’s compact size and low power consumption make it suitable for railway and logistics applications where space and power are limited.

The Verdict: Balancing Reliability and Performance

There’s no one – size – fits – all answer in the fanless vs fan – cooled debate. Hystou’s K4 and H3 – N100 fanless models excel in harsh environments where reliability and low maintenance are critical. They offer silent operation, dust resistance, and a wide operating temperature range.

On the other hand, the H6 Fan – Cooled model is the clear choice when processing power and multi – display capabilities are paramount. It delivers desktop – level performance in a compact form factor, making it suitable for control rooms, research facilities, and other environments where computing demands are high.

The good news is that with Hystou’s diverse product lineup, you don’t have to compromise. You can deploy fanless models on the factory floor where dust and vibration are concerns and use fan – cooled systems in the control room where performance is critical. This hybrid approach ensures optimal performance and reliability across your entire operation.

As industrial computing continues to evolve, Hystou’s commitment to both fanless ruggedness and fan – cooled performance positions them well to meet the diverse needs of modern industries. Whether you’re building the smart factory of the future or upgrading legacy systems, Hystou has an industrial mini PC solution that fits your specific requirements.

HYSTOU

HYSTOU has established its R&D headquarters in Shenzhen, drawing on over a decade of experience. Our core team members, who previously served at renowned companies such as Inventec and Quanta Computer, form the backbone of our technical expertise. With robust R&D and innovation capabilities, we remain steadfast in our commitment to pursuing excellence in the field of technology products.