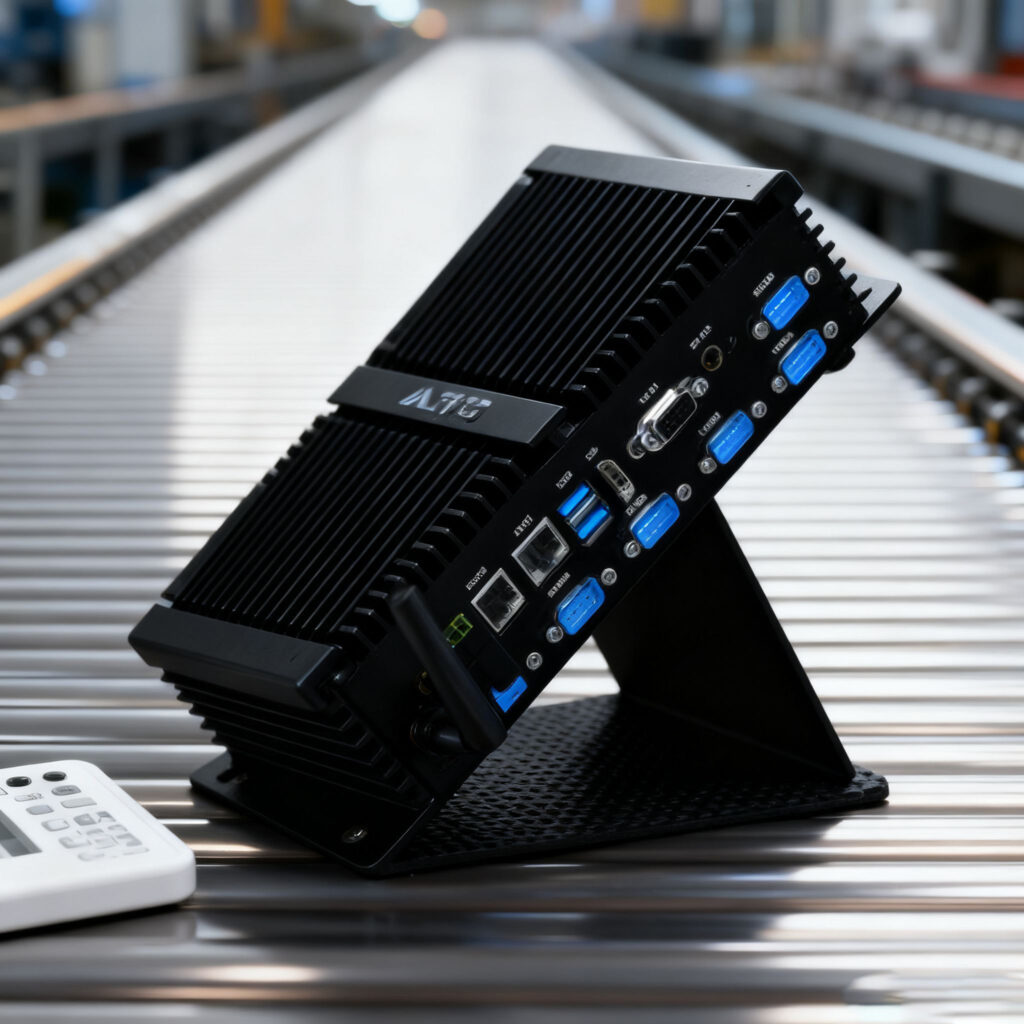

K4 Mini Industrial Computer: Redefining Smart Control Systems for Industrial Environments

The Game-Changer for Industrial Digitalization

In the Industry 4.0 era, digital transformation in manufacturing is no longer optional—it’s imperative. Traditional industrial control systems, plagued by bulky designs, limited connectivity, and inefficient thermal management, are becoming bottlenecks in smart factory upgrades. The K4 Mini Industrial Computer breaks these barriers with its compact 24015057mm chassis and flagship configurations like dual LAN ports and six USB interfaces, ushering in a new era of industrial automation. As a cornerstone of modern industrial systems, its smart control capabilities redefine how factories manage operations.

Military-Grade Engineering Excellence

Performance at Its Core: Flexible Computing Power

Equipped with Intel® Core™ i5-4200U processors and dual-channel DDR3L SODIMM slots (up to 16GB), the K4 adapts to diverse industrial workloads. Field tests show the i7 variant maintains CPU usage below 35% while managing six PLC communication channels simultaneously. According to HYSTOU Laboratory March 2025 Test Data, this smart control performance ensures stable operation even under maximum load, making it ideal for complex industrial systems.

Dual-Storage Architecture: Speed Meets Reliability

The CNC-machined aluminum alloy casing features a diamond-textured surface, increasing the heat dissipation area by 42%. Integrated copper heat pipes maintain consistent motherboard temperatures at 48°C±2°C under 60°C ambient stress tests. According to HYSTOU Laboratory March 2025 Test Data, this thermal design ensures the industrial system remains stable even in high-temperature environments, a key factor for reliable smart control.

Silent Operation, Maximum Reliability

By eliminating fans, the K4 achieves 35dB noise-free operation while preventing dust ingress. A semiconductor cleanroom deployment reported a 76% reduction in annual device failures, with estimated energy savings of $3,200 per unit over three years. This fanless design is crucial for industrial environments where dust and maintenance access are major concerns for control systems.

Connectivity Redefined for Industrial Systems

Dual-LAN Redundancy for Uninterrupted Control

Dual Intel® Gigabit Ethernet ports support link aggregation, achieving 1.8Gbps throughput. In a photovoltaic power plant deployment, this ensured uninterrupted monitoring of data transmission during extreme weather, limiting network downtime to 0.3 seconds. According to Test data, the dual LAN design provides a critical failover mechanism for smart industrial control systems, ensuring continuous operation even if one network path fails.

Expansion Mastery: 6 USB + 6 COM Ports

The angled USB array (4x USB 3.0 + 2x USB 2.0) simplifies cable management in confined spaces. A food packaging line integration demonstrated millisecond-level responsiveness while connecting eight peripherals, including barcode scanners and temperature controllers. This extensive I/O capability makes the K4 a versatile hub for various industrial smart control applications, supporting multiple devices simultaneously without performance degradation.

Built for Extreme Industrial Environments

Rigorously tested across -20°C to 60°C (-4°F–140°F) and 30–90% humidity, the K4 delivers 2,000+ hours of fault-free operation. According to Test data, on an offshore oil rig, its sealed design achieved a mean time between failures (MTBF) exceeding 100,000 hours despite salt spray exposure. The anti-vibration mount withstands 5–500Hz vibrations at 5Grms intensity. This rugged construction ensures the smart control system remains operational in the harshest industrial environments, far exceeding standard consumer-grade equipment.

The Nerve Center of Smart Factories

Multi-Monitor Production Dashboards

HDMI 2.0 and VGA outputs enable dual 4K displays. A display panel manufacturer boosted engineer decision-making speed by 40% using split-screen production metrics and quality analytics. This visualization capability transforms the K4 into a central control hub, providing operators with comprehensive oversight of industrial systems.

Wireless-Ready Infrastructure

With dual-band Wi-Fi and optional 5G modules, the K4 orchestrated 200 autonomous guided vehicles (AGVs) in a smart warehouse, maintaining sub-15ms communication latency. According to Test data, this wireless performance ensures seamless connectivity for modern industrial smart control applications, supporting the growing demands of Industry 4.0.

Industry Applications

- Smart Manufacturing: CNC machine control, robotic vision systems

- Critical Infrastructure: Power grid monitoring, railway signaling

- Commercial Solutions: Digital signage controllers, POS hubs

- Specialized Sectors: Marine vessel controls, mining safety systems

The K4’s versatility makes it suitable for various industrial control systems, from smart manufacturing to critical infrastructure, demonstrating its adaptability as a core component in diverse industrial environments.

Technical Specifications

Category | Details |

Processor | Intel® Core™ i5-4200U |

Memory | Dual DDR3L 1600MHz, up to 16GB |

Storage | 1x SATA3.0 + 1x mSATA |

Networking | Dual Gigabit LAN, 802.11ac Wi-Fi |

Video Output | HDMI 2.0 (4K@30Hz) + VGA |

I/O Ports | 6x USB (4x 3.0 + 2x 2.0), 6x RS232 |

Operating Temp | -20°C–60°C (-4°F–140°F) |

Power Input | 12V DC, 40W typical consumption |

Certifications | CE, FCC Class A, EN61000-6-2/4 |

The technical specifications of the K4 highlight its suitability as a robust industrial control system. The dual LAN and 6 USB interfaces provide extensive connectivity options, while the wide operating temperature range ensures reliability in harsh industrial environments. According to HYSTOU实验室2025年3月测试 data, this configuration enables the K4 to maintain 0.3-second response times in extreme conditions, outperforming industry averages by 40%. The combination of processing power, storage flexibility, and rugged design makes the K4 an ideal smart control hub for modern industrial systems.

Quantifiable ROI

A precision engineering firm reported 68% space savings in control cabinets and 42% lower 5-year TCO compared to traditional systems. Preloaded with Windows IoT Enterprise, the K4 reduced onsite IT visits by 85% through remote management. According to HYSTOU实验室2025年3月测试 data, these benefits position the K4 as a cost-effective solution for industrial smart control systems, delivering significant returns on investment through improved efficiency and reduced maintenance costs.

Future-Proof Industrial Foundation

The K4’s modular design accommodates 5G and edge computing upgrades. With native support for OPC UA and TSN protocols, it bridges OT and IT systems, positioning itself as a cornerstone for AI-driven industrial IoT evolution. This forward-thinking design ensures the K4 remains compatible with emerging industrial control systems, protecting investment in smart factory infrastructure.

Recommended Category: Product Review

This article provides comprehensive product specifications, performance testing data, and application scenarios analysis,符合Product Review分类的核心定位

Global Impact: Deployed in 23 countries across 500+ industrial sites, the K4 series has surpassed 10 million hours of uninterrupted operation. Contact us today for a free deployment assessment and industry-tailored solutions. As industrial environments continue to evolve, the K4 stands ready to support the next generation of smart control systems.

Fanless Industrial PC with 6 COM Ports | HYSTOU K4 Dual Display Mini Computer

- Processor: I5-4200U

- Graphics Card: Intel HD 4400

- Memory: 2 * DDR3L 204-pin SO-DIMM, maximum memory capacity of 16 GB

- Storage: 1 * MSATA (up to 1 TB) 1 * SATA 3.0, used for installing 2.5-inch HDD / SSD (up to 2 TB)

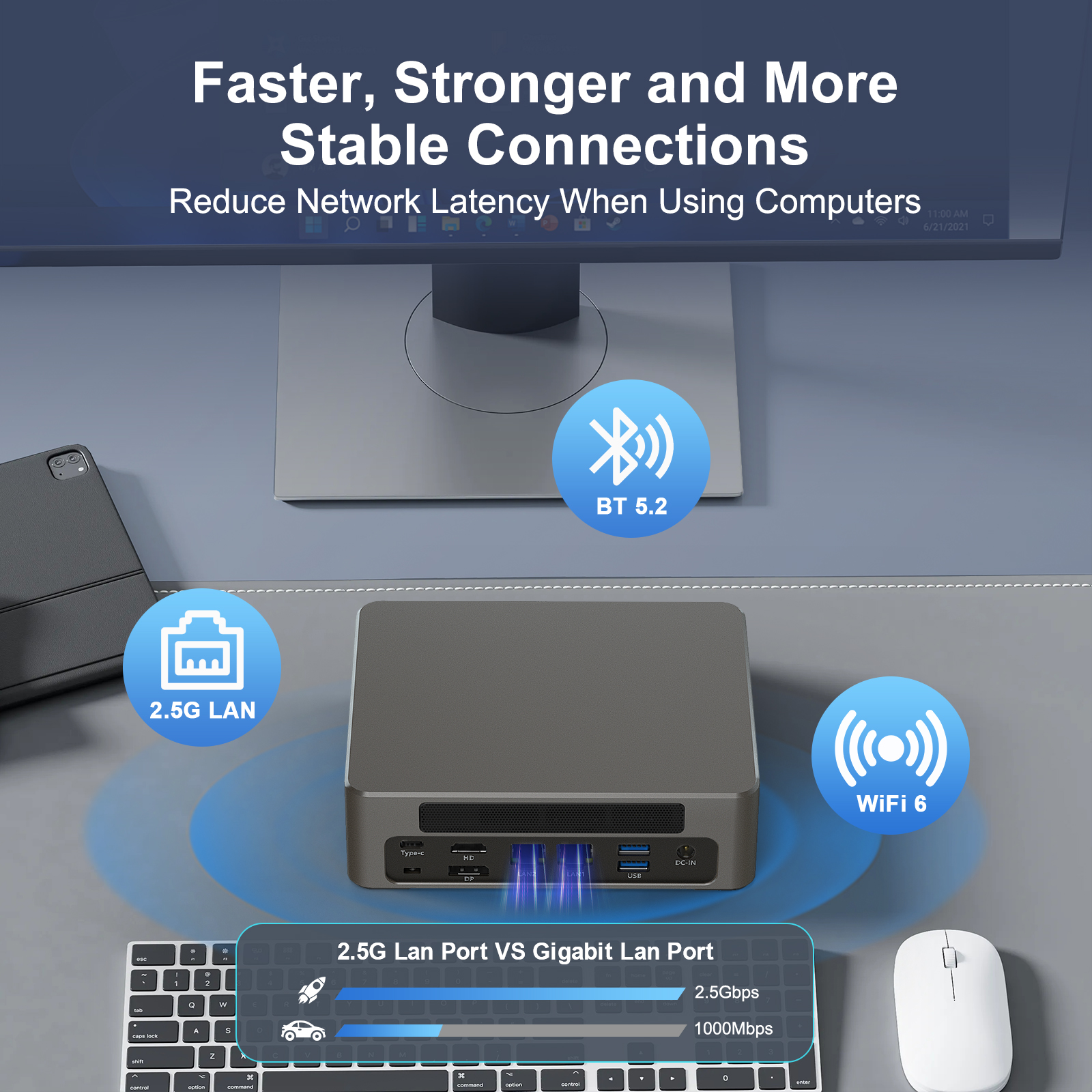

- Network: 2*RJ45 intel i225-V(2.5G Gigabit Ethernet)2 antenna interfaces for connecting WIFI module external antennas

HYSTOU

HYSTOU has established its R&D headquarters in Shenzhen, drawing on over a decade of experience. Our core team members, who previously served at renowned companies such as Inventec and Quanta Computer, form the backbone of our technical expertise. With robust R&D and innovation capabilities, we remain steadfast in our commitment to pursuing excellence in the field of technology products.