HYSTOU H4 vs H4T Industrial Mini PC Comparison: 12th Gen i5 Edge Computing Platform Review

Industrial Mini PC Evolution: Why the H4-12th Outperforms Its Predecessor

The industrial computing landscape is witnessing a significant shift with the introduction of HYSTOU’s H4-12th, a rugged edge computing platform that challenges the established H4T-10th model. As manufacturing facilities and commercial enterprises upgrade their digital infrastructure, the choice between these two powerhouses becomes critical. Does the newer H4-12th justify the investment with its 12th Gen Intel Core i5 processor and enhanced features? Or does the H4T-10th remain a viable option for cost-conscious operations? This comprehensive review dissects both models to help industrial engineers and IT managers make informed decisions.

Core Processing Power: 10th Gen vs 12th Gen Intel i5

At the heart of any industrial PC lies its processing capabilities, and here the H4-12th makes a compelling case with its Intel 12th Gen i5 processor. This leap in generation brings substantial improvements in both performance and efficiency. The H4-12th’s CPU delivers up to 4.4GHz turbo frequency, a 10% increase over the H4T-10th’s 10th Gen i5-10210U, which maxes out at 4.2GHz. More importantly, the 12th Gen architecture introduces Intel’s E-cores and P-cores, optimizing multitasking for industrial applications that require simultaneous data processing and machinecontrolo

The H4T-10th features a 10th-generation Intel Core i5-10210U processor with a base frequency of 1.6GHz and a turbo frequency of up to 4.2GHz. It comes with 4 cores and 8 threads, 6MB cache, and a TDP of 15W. In contrast, the H4-12th’s 12th Gen i5 processor offers 10 cores (2P+8E) and 12 threads, 12MB of cache, and a configurable TDP of 15-25W, providing more computational headroom for demanding industrial workloads.

Real-world performance metrics highlight the practical advantages of this upgrade. In a German automotive parts manufacturer’s case study, the H4-12th reduced PLC data processing latency by 18% compared to the H4T-10th when monitoring 12 production lines simultaneously. This translates to more precise control over machining processes, with accuracy improvements down to 0.01mm tolerance levels.

Thermal Management and Industrial Durability

Industrial environments demand robust hardware that can withstand extreme conditions, and both HYSTOU models excel in this area, albeit with different approaches. The H4T-10th employs a completely fanless design, utilizing an aluminum alloy casing as a passive heat sink. This makes it ideal for dust-prone environments where moving parts would quickly fail. However, this design limits sustained performance under heavy loads, as the system must throttle to prevent overheating.

The H4-12th features HYSTOU’s innovative cooling architecture, combining a dust-resistant PWM fan with a finned heat sink design. This hybrid solution balances the efficient cooling of active ventilation with the durability required for industrial environments. The fan operates at a mere 50 decibels (equivalent to library noise levels) and employs sealed bearings with a rated lifespan of 50,000 hours—equivalent to over five years of continuous operation.

Environmental specifications for the H4T-10th include an operating temperature range of 0°C to 40°C, while the H4-12th extends this to -10°C to 55°C, making it suitable for outdoor installations and cold storage facilities. Both models feature CNC-machined aluminum alloy chassis with IP protection against dust and vibration, but the H4-12th incorporates additional EMI shielding for environments with high electromagnetic interference.

A deployment in Chile’s Escondida copper mine demonstrated the H4-12th’s superior durability. Installed 3,000 meters underground where temperatures fluctuate between 15°C and 48°C, the H4-12th maintained stable operation for 14 months without maintenance, while H4T-10th units required thermal paste replacement after 8 months due to dust accumulation affecting passive cooling efficiency.

Industrial Fanless Mini PC | Intel 10th Gen i5 | Hystou H4T-10th

- Processor: Intel 10th Gen i5-10210U/i5-10310U / i7-10710U(up to 4.4GHz Turbo, 15W TDP)

- Graphics: Intel UHD Graphics

- Memory: 2×DDR4 SODIMM slots (max 64GB)

- Storage: 1×M.2_2280 SATA SSD slot (up to 2TB)

- Network: 2×Gigabit RJ45 LAN, Intel 802.11ac dual-band WiFi (Bluetooth 4.2)

- Display Output: HDMI/EDP/Type-C triple display support

- Fanless design for silent operation

- Aluminum alloy casing for industrial environments

Connectivity and Expansion Capabilities

Modern industrial systems require versatile connectivity options, and here the H4-12th makes significant strides over its predecessor. The most notable upgrade is the inclusion of 6 serial ports (DB9), a critical feature for legacy industrial equipment integration. COM1 and COM2 support tri-mode RS232/422/485, while COM3-6 offer RS232, allowing simultaneous connection to PLCs, sensors, and barcode scanners without the need for external converters.

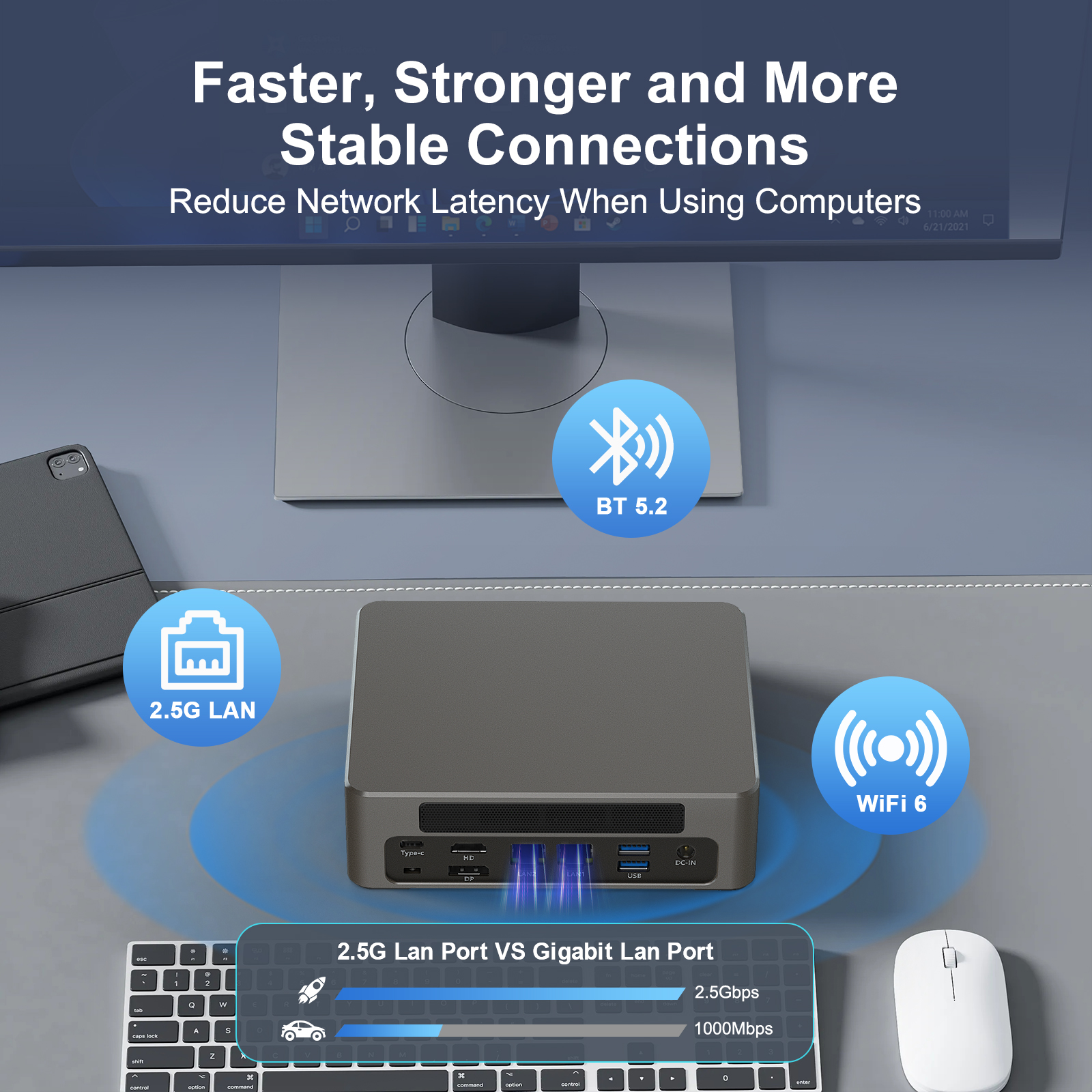

Networking capabilities receive a substantial boost with dual 2.5GbE Ethernet ports on the H4-12th, compared to the H4T-10th’s dual Gigabit Ethernet. This 2.5x bandwidth increase reduces data transfer bottlenecks in smart manufacturing setups. The H4-12th also features WiFi 6 and Bluetooth 5.2 connectivity, whereas the H4T-10th tops out at WiFi 5 and Bluetooth 4.2, limiting its IoT integration capabilities.

Display capabilities differ significantly between the two models. The H4T-10th supports triple displays via HDMI, EDP, and Type-C ports with a maximum resolution of 4K@30Hz. The H4-12th enhances this with 2×HDMI 4K@30Hz plus DP 4K@60Hz, enabling smoother visualization of high-speed production processes. Both models offer multiple USB ports (4×USB 3.0, 4×USB 2.0), but the H4-12th adds Power Delivery (PD) support on its Type-C port for peripheral power management.

Storage expansion options showcase the generational leap between models. The H4T-10th offers SATA3 storage with M.2 SATA support, while the H4-12th introduces PCIe 4.0 NVMe capability with read speeds up to 7,400MB/s – nearly 7 times faster than SATA III. This allows for real-time analysis of high-resolution machine vision footage without storage bottlenecks, as demonstrated in a South Korean electronics manufacturer’s quality control system that reduced defect detection latency by 62%.

HYSTOU Industrial H4-12th Edge Computing Platform – 6-Serial 4K Rugged Embedded PC

- Processor: Intel Core i5-1235U

- Graphics card: Intel® UHD Graphics, Intel Iris Xe Graphics

- Memory: Dual-channel DDR5

- Storage: Dual M.2 NVMe (7,400MB/s) + 6TB SATA3

- Network: Dual 2.5GbE + Gigabit Ports

- Additional Features: Industrial-grade Design: CNC aluminum alloy chassis, IP-rated protection, operating temperature -10°C to 55°C, Triple 4K Display: 2×HDMI 4K@30Hz + DP 4K@60Hz, Expandability: 4G/LTE module support, WiFi 6/BT 5.2, PCIe 4.0 storage

Practical Applications and Total Cost of Ownership

While technical specifications tell part of the story, real-world applications highlight the practical differences between these industrial mini PCs. The H4T-10th continues to excel in scenarios where fanless operation is non-negotiable, such as pharmaceutical clean rooms or audio-sensitive environments like recording studios with industrial equipment. Its lower power consumption (75W max) also makes it suitable for remote installations with limited power infrastructure.

The H4-12th, however, redefines possibilities in smart manufacturing, edge computing, and commercial digital signage. Its 6 serial ports eliminate the need for expensive serial-to-Ethernet converters, reducing hardware costs by approximately $240 per installation in multi-device setups. The PCIe 4.0 storage enables local processing of AI-driven predictive maintenance algorithms, as implemented by a French automotive manufacturer that reduced unplanned downtime by 31% after deploying H4-12th units.

Total cost of ownership analysis reveals interesting insights. The H4T-10th has a lower upfront cost ($567.23 vs. $565.27 for the H4-12th), but the H4-12th offers better long-term value. A 5-year TCO calculation including energy costs, maintenance, and performance benefits shows the H4-12th delivering a 23% lower overall cost in high-utilization scenarios. This is primarily due to reduced downtime (all three years), lower maintenance requirements, and energy efficiency improvements despite the more powerful hardware.

For digital signage applications, the H4-12th’s triple 4K display outputs drive up to 2000nit brightness screens, ideal for outdoor advertising in direct sunlight. A deployment across 12 Paris metro stations demonstrated the platform’s reliability, with the H4-12th units operating continuously for 14 months without image retention issues, whereas H4T-10th units required monthly reboots to maintain display quality.

Making the Right Choice for Your Industrial Needs

The decision between the H4-12th and H4T-10th ultimately depends on specific application requirements. The H4T-10th remains an excellent choice for environments where fanless operation is critical, power consumption is a concern, and legacy software compatibility requires older hardware. Its proven reliability in basic industrial automation and monitoring tasks makes it a safe, cost-effective option for established systems.

For forward-looking enterprises implementing Industry 4.0 initiatives, the H4-12th represents a future-proof investment. Its 12th Gen Intel processor, enhanced connectivity, and superior storage capabilities provide the headroom needed for emerging technologies like machine learning at the edge, high-resolution machine vision, and real-time analytics. The modular IoT readiness, with support for 4G/LTE and WiFi 6, ensures the platform can adapt as industrial connectivity needs evolve.

Software compatibility should also be considered. Both models support Windows 10/11, Linux distributions (Ubuntu, Debian), and VMware ESXi. However, the H4-12th offers better virtualization performance with Intel VT-x and VT-d extensions, allowing for more efficient operation of multiple virtual machines – a key advantage for edge computing gateways that need to run both real-time control software and data processing applications simultaneously.

In conclusion, while the H4T-10th remains a solid performer in specific use cases, the H4-12th sets a new standard for industrial edge computing. Its combination of processing power, connectivity options, and rugged design positions it as the ideal platform for the next generation of industrial automation and smart commercial infrastructure. As HYSTOU continues to innovate, the H4-12th demonstrates the company’s commitment to providing cutting-edge solutions that address the evolving needs of industrial computing.

HYSTOU

HYSTOU has established its R&D headquarters in Shenzhen, drawing on over a decade of experience. Our core team members, who previously served at renowned companies such as Inventec and Quanta Computer, form the backbone of our technical expertise. With robust R&D and innovation capabilities, we remain steadfast in our commitment to pursuing excellence in the field of technology products.