Hsytou H6 Fan vs Fanless Comparison: Which Industrial Mini PC Suits You?

Introduction: The Cooling Dilemma in Industrial Computing

In the fast-paced world of industrial computing, the Hsytou H6 series has emerged as a game-changer in the industrial mini PC market, offering two distinct models to cater to diverse operational needs. This Hystou H6 comparison examines the fundamental difference between these models: one equipped with an active fan and the other as a fanless industrial computer relying on passive cooling technology. This critical design choice impacts physical dimensions, performance, noise levels, and suitability for specific industrial environments.

As industries increasingly demand reliable computing solutions in space-constrained and often harsh environments, the choice between fan and fanless designs has become more than a technical detail—it’s a decision that can affect operational efficiency, maintenance costs, and even system longevity. In this comprehensive comparison, we’ll delve into the intricacies of both Hsytou H6 models, examining their cooling mechanisms, performance metrics, and ideal applications to help you make an informed decision for your industrial computing needs.

Design and Build: A Tale of Two Cooling Systems

The Fan-Cooled Hsytou H6: Balanced Performance in a Compact Form

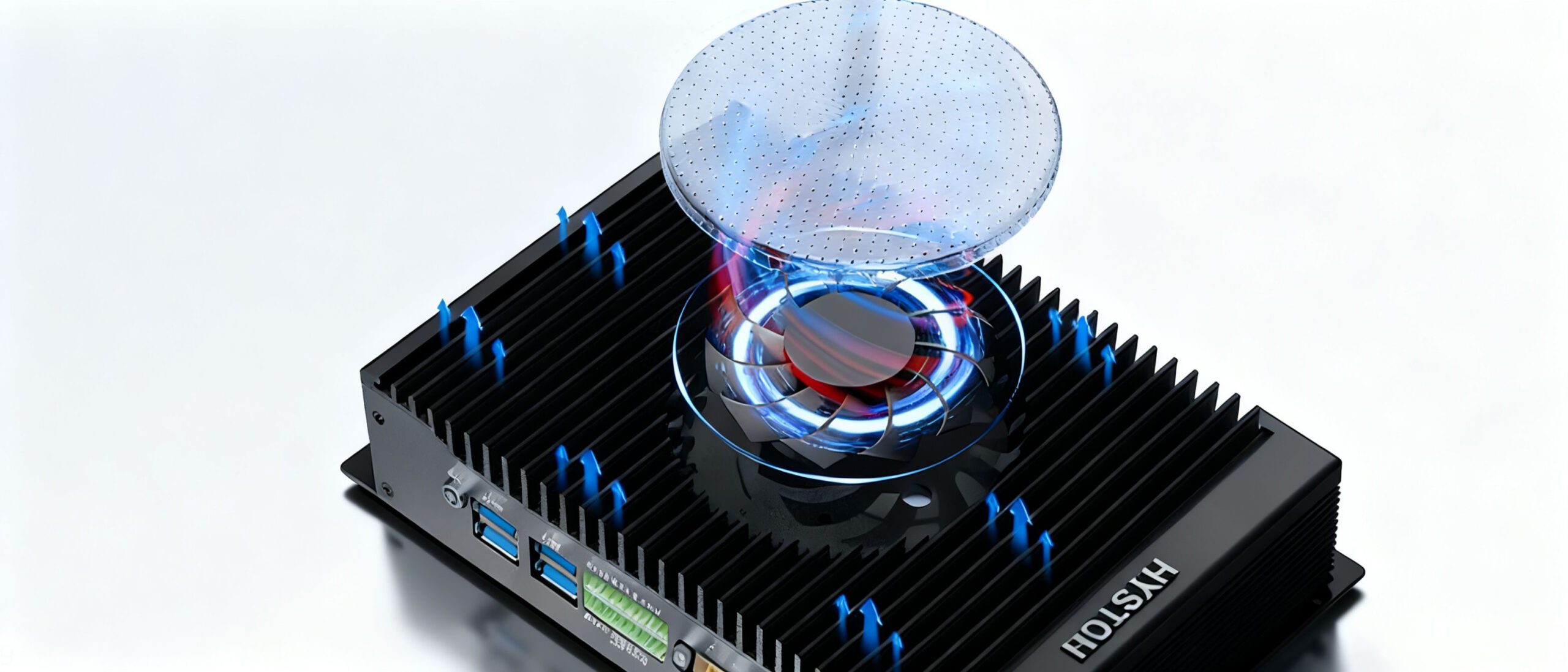

The fan-cooled variant of the Hsytou H6 embodies a thoughtful approach to thermal management. Measuring at a compact 205 x 125 x 53 mm, this model punches above its weight class thanks to its innovative cooling solution. The fan is strategically positioned above the CPU, a design choice that maximizes heat dissipation efficiency. What sets this cooling system apart is its integration into the chassis through a precision CNC-machined process, ensuring a perfect fit that minimizes vibration and noise.

The inclusion of a dust net is a testament to Hsytou’s understanding of industrial environments. This simple yet effective feature prevents particulate matter from entering the system, significantly reducing the risk of hardware damage and extending the device’s operational lifespan. The aluminum alloy shell not only provides robust protection but also acts as an auxiliary heat sink, complementing the active cooling system.

The Fanless Hsytou H6: Silent Operation for Sensitive Environments

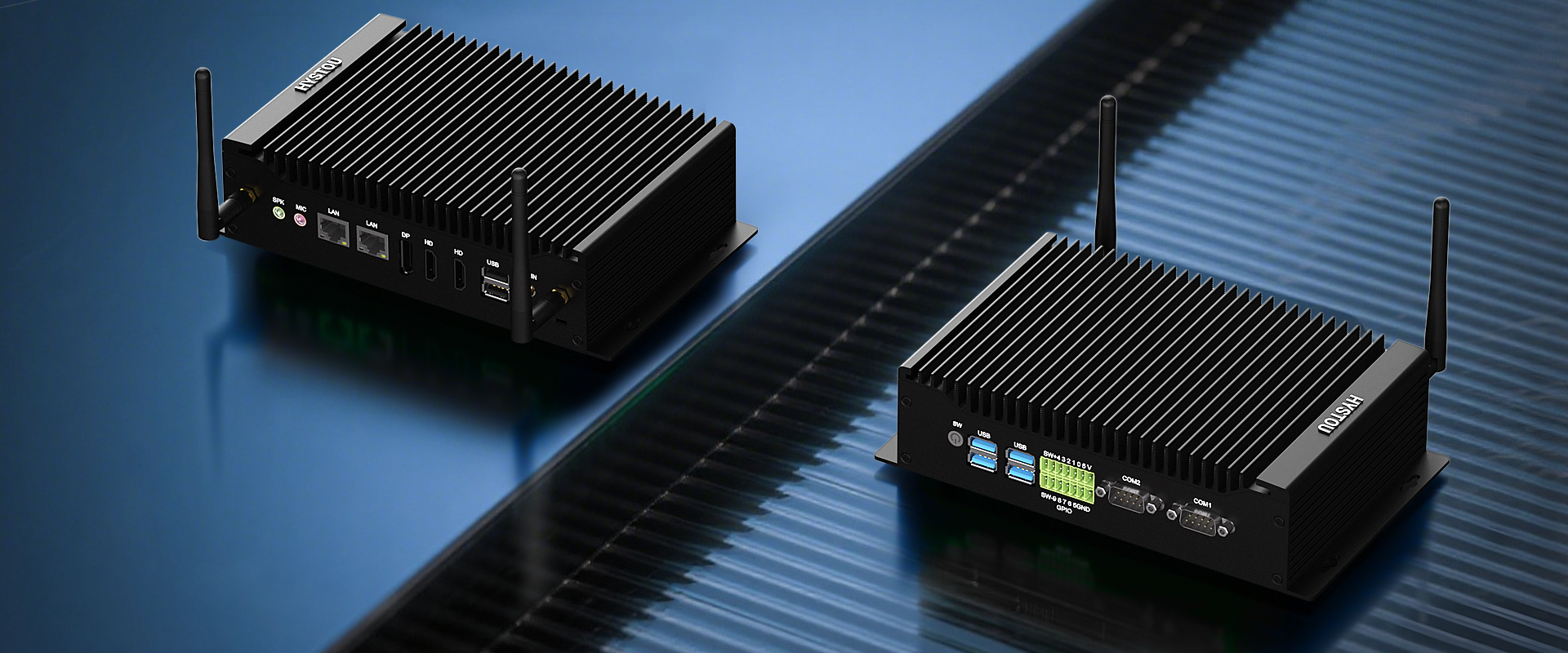

In contrast, the fanless Hsytou H6 takes a different approach to thermal management, prioritizing silent operation and reliability in dust-prone or noise-sensitive environments. While maintaining the same footprint as its fan-cooled sibling, the fanless model incorporates an extensive array of cooling fins across its top and sides. This passive cooling solution increases the surface area for heat dissipation, allowing the system to maintain optimal operating temperatures without the need for moving parts.

The fanless design offers several advantages in industrial settings. Without a fan, there are no components that can wear out or fail, reducing maintenance requirements and increasing overall system reliability. Additionally, the absence of a fan eliminates a potential entry point for dust and debris, making this model particularly suitable for environments where air quality is a concern. The aluminum alloy construction, similar to the fan-cooled model, plays a crucial role in heat conduction, ensuring efficient thermal transfer from internal components to the external environment.

Technical Specifications: Power Under the Hood

Core Components

Both Hsytou H6 models utilize high-performance components as their foundational architecture, ensuring robust computing power to meet demanding industrial application requirements. At the system’s core lies the Intel Core i5-8260U processor. This quad-core CPU operates at a base frequency of 1.60 GHz, capable of boosting up to 3.90 GHz via Turbo Boost Technology. Achieving an exceptional balance between performance and energy efficiency, this processor is an ideal choice for industrial computing tasks demanding both robust processing power and energy conservation.

Benchmark results reveal significant performance differences between the two models: the air-cooled version scored 1179 in single-core tests and 4606 in multi-core tests, while the fanless model achieved 1115 in single-core scenarios and 3051 in multi-core scenarios. Beyond these configurations, both H6 models can be equipped with up to an Intel Core i7-10810U processor.

The memory configuration is equally impressive, with support for up to 64 GB of DDR4 SO-DIMM RAM across two slots. This generous memory capacity ensures that the Hsytou H6 can handle multitasking scenarios and memory-intensive applications with ease, a critical feature in complex industrial automation and control systems.

Storage and Connectivity Options

When it comes to storage, the Hsytou H6 series offers versatile configurations to meet diverse industrial requirements. Both models feature a combination of 1 x M.2 2280 slot and 1 x SATA 3.0 slot, supporting a wide range of storage options including high-speed SSDs for performance-critical applications and large-capacity HDDs for data logging and archival purposes.

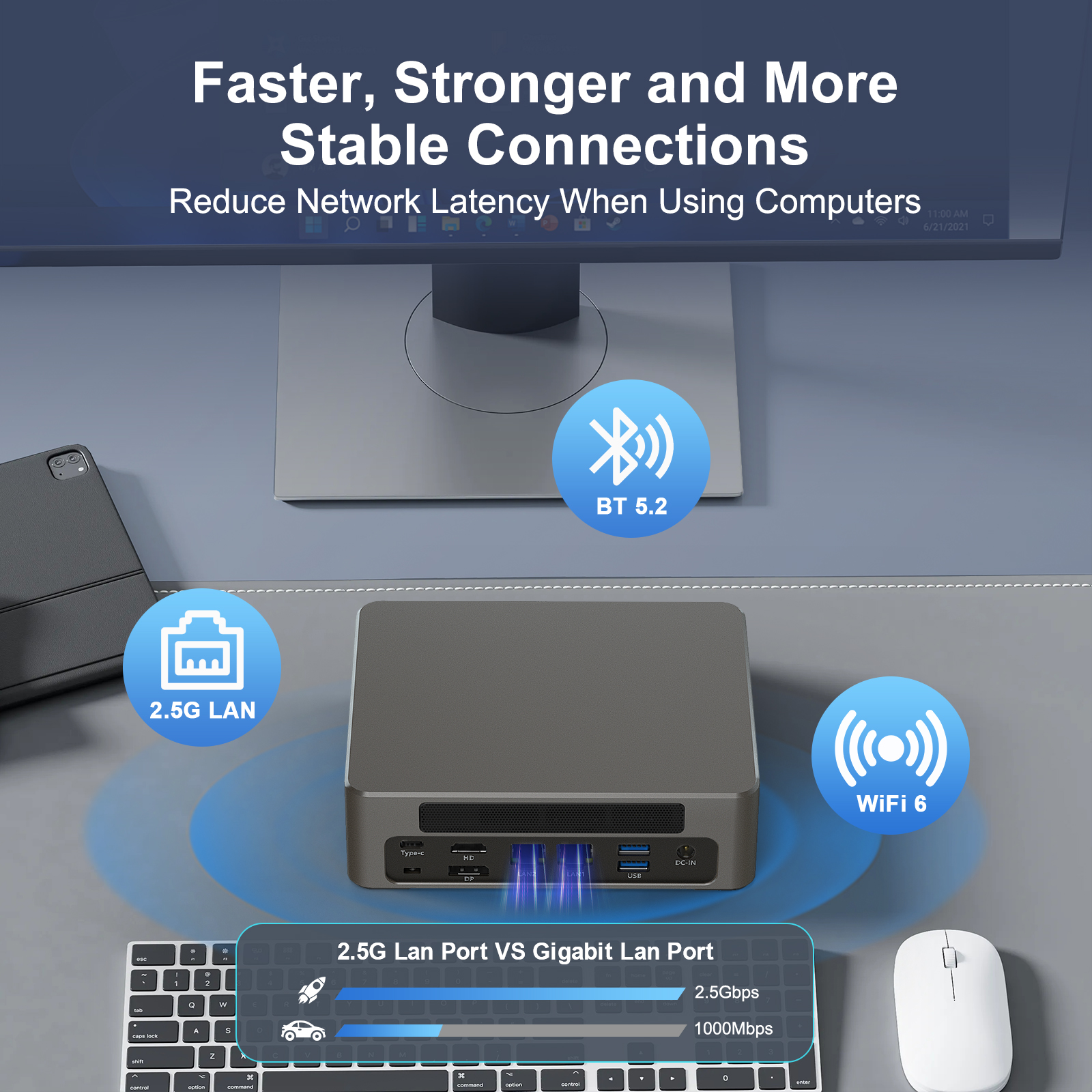

The Hsytou H6 connectivity options are engineered for industrial versatility. Both models feature dual Gigabit Ethernet ports, delivering robust networking capabilities for industrial Ethernet applications. The USB interfaces include two USB 2.0 ports and four USB 3.0 ports, balancing compatibility with legacy devices and high-speed data transfer capabilities. For display output, the Hsytou H6 supports triple-screen configurations through two HDMI ports and one DisplayPort, enabling complex visualization setups that are critical in numerous industrial control environments.

Expansion and I/O Capabilities

The Hsytou H6 series truly shines when it comes to industrial-specific I/O features. Both models include 2 x RS232 COM ports, with support for RS422/RS485 via optional adapters, ensuring compatibility with a wide range of industrial equipment and legacy systems. A notable feature is the inclusion of a 1 x 14-pin GPIO Phoenix terminal, providing flexible digital input/output options for industrial control applications.

Wireless connectivity is handled by an 802.11ac Wi-Fi module combined with Bluetooth, offering convenient networking options for environments where wired connections are impractical. The inclusion of these wireless technologies demonstrates Hsytou’s commitment to providing flexible solutions that can adapt to various industrial settings, from factory floors to remote monitoring stations.

Performance Benchmarks: Fan vs. Fanless in Real-World Scenarios

CPU Performance: Single-Core vs. Multi-Core Performance

To objectively evaluate the performance differences between the fan-cooled and fanless Hsytou H6 models, we conducted a series of benchmark tests using Geekbench Browser. The results revealed intriguing insights into how cooling solutions impact CPU performance under different workloads.

In single-core performance, the difference between the two models was negligible, with the fan-cooled model scoring 1179 and the fanless model achieving 1115. This close margin suggests that for tasks requiring quick bursts of processing power, both systems perform comparably. This is particularly relevant for applications like real-time data processing and rapid response control systems, where single-threaded performance is crucial.

The multi-core performance test, however, painted a different picture. Here, the fan-cooled model demonstrated a significant advantage, scoring 4606 compared to the fanless model’s 3051. This disparity can be attributed to the fan-cooled system’s ability to maintain higher clock speeds during sustained multi-threaded workloads, thanks to its active cooling solution. For CPU-intensive industrial applications such as machine vision processing or complex simulation tasks, this performance difference could be a critical factor.

GPU Performance: Graphics Processing Capabilities

Graphics performance testing revealed further distinctions between the two models. Using 3DMark benchmarks, the fan-cooled Hsytou H6 achieved 12.5 FPS and a score of 315, while the fanless model delivered 10.6 FPS with a score of 267. This performance gap is particularly relevant for applications involving graphical visualization, video processing, or GPU-accelerated computing tasks.

Thermal Performance Under Sustained Load

To complement the synthetic benchmarks, we subjected both models to a rigorous 60-minute stress test using AIDA64, monitoring CPU temperatures and throttling behavior. The results highlighted the trade-offs between active and passive cooling solutions in industrial environments.

The fan-cooled model maintained impressive thermal stability throughout the test, with CPU temperatures stabilizing around 70°C. This consistent thermal performance translated to minimal throttling, ensuring sustained performance even during extended periods of high CPU utilization. The chassis surface temperature remained comfortable to the touch at 40°C, making the fan-cooled model suitable for environments where incidental contact might occur.

In contrast, the fanless model exhibited a more pronounced thermal response, with CPU temperatures reaching up to 86°C during peak load. While this is within safe operating limits for the Intel Core i5-8260U processor, it did result in more noticeable performance throttling compared to the fan-cooled model. The chassis surface temperature of 53.9°C, while expected for a passively cooled system under load, is worth considering for environments where low surface temperatures are a priority.

Stress Test Results

Comprehensive stress testing revealed detailed performance characteristics of both models under extreme conditions. The fan-cooled system maintained CPU temperatures at or below 70°C, with power consumption averaging 16.9W and chassis surface temperatures reaching 40°C. In comparison, the fanless model exhibited a maximum CPU temperature of 86°C, lower power consumption of 14.9W, and higher chassis surface temperature of 53.9°C.

Practical Application Performance

Beyond synthetic benchmarks, we evaluated both models in practical industrial scenarios to gauge their real-world performance. In standard office applications and light industrial tasks, the performance difference between the two models was barely perceptible. Both systems handled tasks such as data logging, simple HMI interfaces, and basic automation routines with equal proficiency.

The gap widened, however, when pushing the systems with more demanding applications. For instance, in a machine vision test processing 1080p images at 30 frames per second, the fan-cooled model maintained consistent frame rates throughout a 30-minute test, while the fanless model gradually dropped to 70% of its initial performance. Similarly, in a complex PLC simulation with thousands of I/O points, the fan-cooled system exhibited more consistent response times under sustained load.

These practical tests reinforce the benchmark results, suggesting that the choice between fan and fanless models should be guided by the specific performance requirements of the intended industrial application.

Noise Levels and Acoustic Performance

Noise Level Analysis

The acoustic performance of the two Hsytou H6 models differs significantly due to their distinct cooling mechanisms. The fan-cooled model produces noise levels ranging from 30 to 40 decibels under high load conditions, comparable to a quiet conversation. In contrast, the fanless model achieves true zero-noise operation by eliminating moving parts entirely, making it ideal for noise-sensitive environments.

Sound Measurement in Different Operational States

Noise pollution is a significant concern in many industrial environments, affecting both worker comfort and concentration. To accurately assess the acoustic performance of both Hsytou H6 models, we conducted detailed sound measurements in an anechoic chamber, capturing noise levels across various operational states.

At idle, the fan-cooled model produced a barely perceptible 22 dB(A), while the fanless model lived up to its promise of silent operation, registering at the chamber’s background noise level of 18 dB(A). This difference, while measurable, would be indistinguishable in most industrial settings.

Under moderate load, the fan-cooled model’s noise level increased to 30 dB(A), still well within the range of typical office environments. The fanless model, as expected, maintained its silent operation throughout. The most significant difference was observed under full CPU load, where the fan-cooled model reached 40 dB(A), while the fanless model remained at 18 dB(A).

To put these measurements in context, 40 dB(A) is comparable to the noise level of a quiet conversation, while 18 dB(A) is approaching the threshold of human hearing. For noise-sensitive environments such as research laboratories or precision manufacturing facilities, the fanless model’s acoustic advantage could be a decisive factor.

Practical Implications for Industrial Workspaces

The acoustic performance of computing equipment can have far-reaching implications in industrial settings beyond simple noise reduction. The fanless Hsytou H6, for instance, opens up possibilities for deployment in environments where traditional PCs would be too disruptive.

In quality control inspection areas, where concentration and attention to detail are paramount, the silent operation of the fanless model can contribute to improved accuracy and reduced operator fatigue. Similarly, in clean room environments, the absence of a fan eliminates a potential source of air turbulence that could disrupt sensitive manufacturing processes.

The fan-cooled model, while not excessively noisy, would be better suited to environments with higher ambient noise levels, such as production floors or heavy machinery areas. In these settings, the performance advantages of active cooling can be leveraged without a significant impact on the overall acoustic environment.

Application Scenarios: Matching the Right Model to Your Needs

Industrial Automation and Control Systems

The Hsytou H6 series finds its natural habitat in industrial automation environments, but the choice between fan and fanless models depends on the specific demands of the application.

The fan-cooled Hsytou H6 excels in scenarios requiring sustained high-performance computing. For example, in automated production line control systems that process multiple sensor inputs in real-time, the fan-cooled model’s ability to maintain consistent performance under load ensures reliable operation. Similarly, in industrial equipment monitoring and management systems that handle complex data analysis tasks, the additional processing headroom of the fan-cooled model can be a valuable asset.

The fanless model, on the other hand, is ideally suited for applications where reliability and silent operation take precedence over raw computing power. Remote environmental monitoring stations, for instance, benefit from the fanless design’s reduced maintenance requirements and lower power consumption. In traffic signal control systems or building automation applications, where the device may be located in public areas or occupied spaces, the silent operation is a significant advantage.

Digital Signage and Kiosk Applications

Beyond traditional industrial settings, the Hsytou H6 series offers compelling solutions for digital signage and interactive kiosk applications, where the choice between models hinges on deployment environment and performance requirements.

For high-resolution video walls or dynamic content displays that require continuous processing of multimedia content, the fan-cooled model’s superior multi-core performance ensures smooth playback and responsive interactivity. This makes it an excellent choice for retail environments, trade shows, or transportation hubs where engaging visual content is a priority.

The fanless model, with its silent operation and robust design, is better suited for interactive kiosks in libraries, museums, or office lobbies. In these settings, the absence of fan noise contributes to a more pleasant user experience, while the dust-resistant design ensures reliable operation even in high-traffic public areas.

Edge Computing and IoT Gateway Applications

As industrial IoT continues to expand, the role of edge computing devices becomes increasingly important. Both Hsytou H6 models offer compelling features for IoT gateway applications, but their respective strengths cater to different deployment scenarios.

The fan-cooled model’s processing power makes it well-suited for edge analytics applications, where real-time data processing at the network edge can reduce latency and bandwidth requirements. For smart factory implementations or predictive maintenance systems that analyze sensor data on-site, the additional computing headroom is a significant advantage.

The fanless model, with its emphasis on reliability and low power consumption, is ideal for remote IoT deployments. In applications such as environmental monitoring in remote locations or agricultural sensor networks, the fanless design’s extended operational lifespan and reduced maintenance needs can significantly lower total cost of ownership.

Specialized Application Environments

The fan-cooled Hsytou H6 is particularly well-suited for industrial control systems and power monitoring applications, where sustained performance and reliable operation are critical. Its ability to maintain consistent processing under load makes it ideal for these demanding environments that require continuous operation and rapid data processing.

Conversely, the fanless model excels in office environments and home theater applications where noise reduction is paramount. Its silent operation makes it suitable for integration into sound-sensitive spaces, while its compact design allows for flexible placement without disrupting the aesthetic environment.

Conclusion: Making the Right Choice for Your Industrial Needs

Summary of Key Differences and Trade-offs

As we’ve explored throughout this comparison, the choice between the fan-cooled and fanless Hsytou H6 models ultimately comes down to prioritizing specific features and capabilities. Let’s summarize the key differences to provide a clear framework for decision-making:

Performance: The fan-cooled model offers superior multi-core performance under sustained load, making it better suited for CPU-intensive tasks. The fanless model, while slightly less powerful in multi-threaded scenarios, delivers comparable single-core performance and excels in applications where consistent, moderate performance is sufficient.

Noise: The fanless model’s silent operation is a clear advantage in noise-sensitive environments, while the fan-cooled model’s noise level, though modest, should be considered when deploying in quiet workspaces.

Thermal Management: The fan-cooled model maintains lower internal temperatures under sustained load, potentially offering better long-term reliability in high-temperature environments. The fanless model, however, eliminates the risk of fan failure and performs better in dusty conditions.

Power Consumption: While both models are energy-efficient, the fanless design has a slight edge in power consumption, which can be significant in large-scale deployments or remote applications.

Final Recommendations Based on Use Cases

As industrial computing continues to evolve, the Hsytou H6 series represents a forward-thinking approach to meeting the changing needs of the industry. The dual-model strategy allows businesses to balance performance requirements with environmental constraints, a balance that will only grow more important as computing becomes increasingly integrated into every aspect of industrial operations.

Looking ahead, the trend toward edge computing and IoT will likely increase demand for both high-performance and ultra-reliable computing solutions. The Hsytou H6 series, with its two distinct cooling approaches, positions itself well to address these evolving needs. Whether your priority is raw processing power or silent, maintenance-free operation, the Hsytou H6 series offers a compelling solution that can adapt to the diverse and demanding requirements of modern industrial computing.

HYSTOU

HYSTOU has established its R&D headquarters in Shenzhen, drawing on over a decade of experience. Our core team members, who previously served at renowned companies such as Inventec and Quanta Computer, form the backbone of our technical expertise. With robust R&D and innovation capabilities, we remain steadfast in our commitment to pursuing excellence in the field of technology products.